Surface Engineering

By DarthVader

Date: 2022-07-13

Topic: 147 see comments

Post views: 1055

Surface Engineering

Quite often, the key properties required from a product apply mostly to its surface. For example, it might be required to be hard, or corrosion resistant, or a certain colour. Under these circumstances, it can be more practical and cost-effective to change the properties of just the surface rather than the whole product. This approach is known as surface engineering.

Scratch-resistant coating

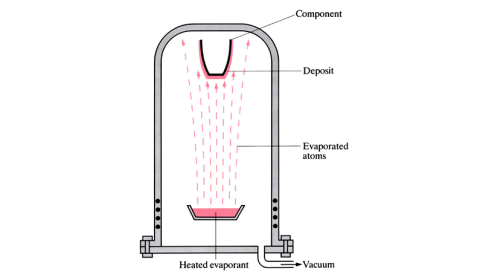

Physical vapour deposition (PVD) is a surface coating technique in which the coating material and the object to be coated are both placed in a vacuum chamber and the coating material is made to evaporate by heating or ion bombardment.

Although the coating material may need to be heated, the surface to be coated - often referred to as the substrate - can be at a relatively low temperature (in the range 50-500 °C). However if the coating is being deposited onto a polymer, then special care must be taken with PVD to avoid heating and thereby distorting or melting the polymer material.

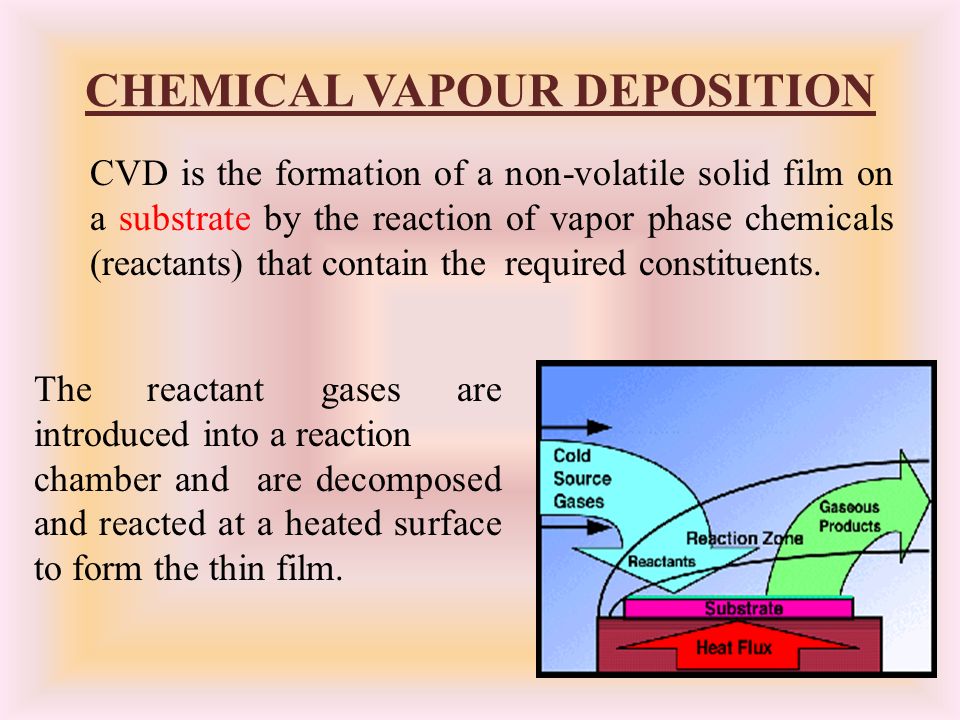

Alternative methods include chemical vapour deposition (CVD), dipping or spin coating. The advantage with the dip or spi coating is the speed with which it can be applied. However in some cases, a PVD or CVD coating can be much more effective in creating an even coating that adheres well to the surface.

Coating types:

- Diamond-like carbon (DLC) - is a particularly effective scratch-resistant coating that offers many of the properties of diamond. It gives a wear-resistant chemical barrier, and can be applied to metal, ceramic, glass and plastic. It is optically transparent and extremely hard.

- Titanium nitride (TiN) - ion plating is a method used commercially to produce films of titanium nitride, a very hard ceramic material used for applications where a hard, sharp, wear-resistant edge is needed - for example, as a coating for kitchen knives.

Thermal barrier coating

Application of thermal barrier coatings in jet aircraft engines and gas turbine engines.

To increase the efficiency of aero engines they need to operate at extremely high temperature. The thermal barrier coating acts as insulation and reduces the temperature that the metal substrate experiences by several hundred degrees Celsius.

Medical Applications

To apply coatings on teeth implants or jaw repairs and also for hip and knee replacements.

| Comments | Creator | Date | ID |

|---|